Docta Reacta: Continuing our discussion, I thought we should provide you with some of the trade-offs when using harmonic filter reactors in harmonic filter bank applications.

The construction methods for trap reactors lend themselves to a substantial flexibility in specifications and ratings. For filter bank applications, single phase iron core reactors are most often utilized because of the flexibility and inherently higher ratings. Copper winding is frequently chosen when performance and size are the driving considerations and aluminum when cost is the design driver.

Power Magnetics has verified BIL (Impulse) rating designs up to 170kV through independent labs testing at KEMA. Most common ratings used are 125kV and 150kV for harmonic filter reactors, particularly when used in filter bank applications in remote regions.

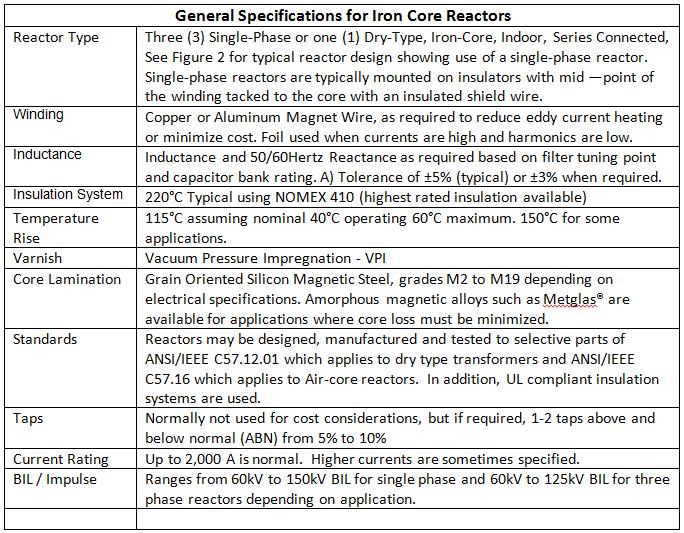

The following table provides a general overview of the harmonic filter reactors

The construction methods for trap reactors lend themselves to a substantial flexibility in specifications and ratings. For filter bank applications, single phase iron core reactors are most often utilized because of the flexibility and inherently higher ratings. Copper winding is frequently chosen when performance and size are the driving considerations and aluminum when cost is the design driver.

Power Magnetics has verified BIL (Impulse) rating designs up to 170kV through independent labs testing at KEMA. Most common ratings used are 125kV and 150kV for harmonic filter reactors, particularly when used in filter bank applications in remote regions.

The following table provides a general overview of the harmonic filter reactors

The nearly ‘bullet-proof’ single phase trap reactors are built using proprietary design and construction methods resulting in units that are smaller, more efficient, run cooler and quieter than the equivalent competitive product. So much so that customers have told us that it was disconcerting for their engineering and manufacturing teams to switch to Power Magnetics iron core harmonic reactors.

We have heard the same thing about our transformers as well. Not infrequently Power Magnetics has been labeled as having ‘a more intelligent’ design for our reactors and transformers. As a matter of fact, this past week the CEO of an induction furnace company commented how Power Magnetics had made a significant contribution to the customer acceptance and reliability of their product lines based our ‘more intelligent design’ practices.

Up next, we will discuss some of the design criteria for your ongoing enlightenment, edification and amazement!

Until then, happy harmonics. This is Docta Reacta signing off!

We have heard the same thing about our transformers as well. Not infrequently Power Magnetics has been labeled as having ‘a more intelligent’ design for our reactors and transformers. As a matter of fact, this past week the CEO of an induction furnace company commented how Power Magnetics had made a significant contribution to the customer acceptance and reliability of their product lines based our ‘more intelligent design’ practices.

Up next, we will discuss some of the design criteria for your ongoing enlightenment, edification and amazement!

Until then, happy harmonics. This is Docta Reacta signing off!