About UsManufacturers of Transformers, Reactors and Power Quality Solutions

|

Established in 1968

The Power Magnetics Manufacturing Team includes the industry's finest craftsmen, dedicated to "doing it the right way". This, in combination with our ISO 9001: 2015 quality program, ensures you only the highest quality magnetics. Our customers have seen how rugged our transformers are, both mechanically and electrically, - built to "take the abuse!" - and how they are built to last. In fact, our motto, “Built like the Brooklyn Bridge” tells the story in an interesting way. Click here to read about our motto.

Why Power Magnetics, Inc.?

If you are looking for quality, reliability and performance in your transformer manufacturer, look no further! Power Magnetics, Inc.’s transformers and reactors are known throughout the industry globally for the elegance of the engineering that gives them unparalleled performance and reliability. In fact, to us each design is a work of art from the engineering perspective, so much so we call it BBE (Built Like the Brooklyn Bridge Engineering). As a manufacturer of power distribution units for specialized applications, Power Magnetics has transformers in every location that the US government has a presence across the globe.

Power Magnetics is an ISO 9001:2015 Certified company for the design and manufacture of transformers, AC reactors and DC inductors. As a manufacture of power distribution units and uninterruptable power units for electrical substations we must exceed your expectations for quality.

Click here for certificate.

We build our units with the same inspiration that went behind our favorite engineering marvel, the Brooklyn Bridge. It turns out there is a significant link between Trenton, NJ and the bridge most people are unaware of.

Built more than 100 years ago, it continues to serve way beyond its original design life and is projected to continue into the foreseeable future. Click here to read the rest of the story!

Power Magnetics is an ISO 9001:2015 Certified company for the design and manufacture of transformers, AC reactors and DC inductors. As a manufacture of power distribution units and uninterruptable power units for electrical substations we must exceed your expectations for quality.

Click here for certificate.

We build our units with the same inspiration that went behind our favorite engineering marvel, the Brooklyn Bridge. It turns out there is a significant link between Trenton, NJ and the bridge most people are unaware of.

Built more than 100 years ago, it continues to serve way beyond its original design life and is projected to continue into the foreseeable future. Click here to read the rest of the story!

Capabilities

Power Magnetics offers a full range of engineering and manufacturing capabilities to build products to your most exacting needs, specifically for your application.

|

Cores: Power Magnetics produces our cores using grain oriented silicon steel from grades M2 to M19. Premade cores of EI and UI laminations, C and DG cores are also available.

|

Windings: aluminum and copper are standard, the latter used when size and performance are the design drivers. Winding may be in sheet or wire and are produced on either semi-automatic or manual winding machines depending on the volume.

|

Enclosures: Power Magnetics has a line of custom designed NEMA 1 and NEMA 3R (outdoor) enclosures with ANSI 61 gray power coat paint finish. Stainless steel enclosures can be custom ordered.

|

Finishing: Operations include varnish, using our atmospheric dip tank, a large VPI chamber and curing in gas fired bake out ovens.

|

Testing: Complete electrical testing lab for high power testing. C of C (Certificates of Compliance) and test results can be requested at the time the order is placed.

|

Our Team

One of the first things a visitor notices at the Power Magnetics office in Trenton is the collection of the Brooklyn Bridge artwork covering the walls. “Despite being an electrical engineer, I have always been fascinated by bridges and the Brooklyn Bridge in particular” said Carl A. Bannwart, Power Magnetics’ president. The bridge was one of the great engineering marvels of the 19th century, and, astoundingly, is expected to last to the 22nd century. John Roebling used many groundbreaking innovations in design and construction, and the quality of the engineering speaks for itself. Also, Roebling’s unique vision included an esthetic grace and elegance rarely matched.“As a student of the bridge, I gradually realized its symbolic value – as well as the obvious Trenton connection with the Roeblings and steel – was important to Power Magnetics, and in fact is emblematic of our mission of innovation, engineering, and endurance. We are proud to say that our products are ‘Built like the Brooklyn Bridge’,” stated Carl A. Bannwart.

Our Motto

Power Magnetics, Inc. — Built Like the Brooklyn Bridge

The Brooklyn Bridge, designed by John Augustus Roebling and built by his son, Washington Roebling, both of Trenton, New Jersey, is one of the great engineering marvels of the 19th century, having been completed in 1883. The largest span of any bridge of its time, the Brooklyn Bridge remained the largest in the world for 20 years. The engineering genius of John Augustus Roebling innovated basic concepts that are state of the art to this very day. For instance, if those concepts had they been adhered to, the spectacular failure of the Tacoma Narrows Bridge in 1940, would have been prevented. The Senior Roebling's unique vision included not only structural integrity beyond dispute, but also an aesthetic grace and elegance rarely matched.

The suspension bridge continually receives punishing use and has endured well, despite loads many times what Roebling originally designed for. Today the bridge is one of America's greatest icons, admired by people from around the world. It is undergoing a massive renovation, and is expected to last well into the 22nd century.

Power Magnetics is a proud inheritor of the engineering and manufacturing tradition initiated by the Roeblings in Trenton. Claiming this mantel, we are proud to say that our products are "Built like the Brooklyn Bridge."

- Carl A. Bannwart, President Power Magnetics, Inc.

Photo: Brooklyn Bridge by rãvi, on Flickr

Power Magnetics, Inc. is the recognized leader in design and manufacturing of the industry’s highest performance and most reliable premium custom transformers, AC reactors and DC inductors. Since 1968, we have built custom magnetics for our global customers, some of the largest companies in the world, which exemplifies the three pillars of our philosophy: Innovation, Engineering and Endurance. You simply cannot buy a higher quality air cooled transformer or reactor. Period.

Innovation: Our proprietary design methods assure our customers that our transformers, inductors and reactors are the highest performance magnetics for the given application. We go deeper than anyone, down to the physics of the devices to provide the innovation our customers have come to expect to solve their problems. In particular, our line of reactors, including trap reactors, line reactors, saturable reactors, current limiting reactors (CLR’s) are best of breed in the market place.

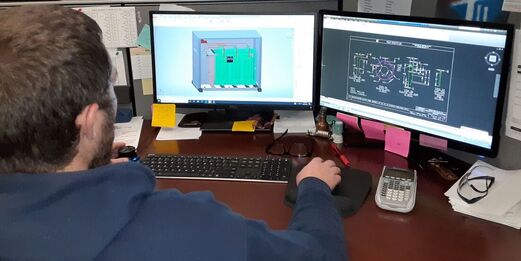

Engineering: Solid engineering design begins with the most advanced magnetics design software in the market, backed up with decades of design experience across a broad spectrum of products in transformers, reactors and inductors. Our engineering department has over 120+ years in custom magnetics design and fabrication of transformers, iron core reactors and air core reactors. We also take seriously our motto, “Built Like The Brooklyn Bridge”, applying what we term Brooklyn Bridge Engineering, B2E for short, as the inspiration for making the designs a work of art besides a masterpiece of engineering excellence!

Endurance: At the end of the day, the over-riding concern for our customers is reliability of their products in the field. Our conservative design, engineering and ISO certified manufacturing practices provide premium custom magnetics that our customers have come to count on for years of trouble free service in the most demanding applications. More than once we have heard from customers, “Practically indestructible,” when describing our products. Our customers in the oil & gas, transportation, automotive and electric vehicle, manufacturing, commercial facilities, communications, energy industries and renewable energy, know they can count on our drive isolation and neutral grounding transformers, load banks, trap reactors, line reactors, furnace transformers, plate transformers, and AC and DC inductors to provide literally decades of trouble free service, in the harshest of environments.

The suspension bridge continually receives punishing use and has endured well, despite loads many times what Roebling originally designed for. Today the bridge is one of America's greatest icons, admired by people from around the world. It is undergoing a massive renovation, and is expected to last well into the 22nd century.

Power Magnetics is a proud inheritor of the engineering and manufacturing tradition initiated by the Roeblings in Trenton. Claiming this mantel, we are proud to say that our products are "Built like the Brooklyn Bridge."

- Carl A. Bannwart, President Power Magnetics, Inc.

Photo: Brooklyn Bridge by rãvi, on Flickr

Power Magnetics, Inc. is the recognized leader in design and manufacturing of the industry’s highest performance and most reliable premium custom transformers, AC reactors and DC inductors. Since 1968, we have built custom magnetics for our global customers, some of the largest companies in the world, which exemplifies the three pillars of our philosophy: Innovation, Engineering and Endurance. You simply cannot buy a higher quality air cooled transformer or reactor. Period.

Innovation: Our proprietary design methods assure our customers that our transformers, inductors and reactors are the highest performance magnetics for the given application. We go deeper than anyone, down to the physics of the devices to provide the innovation our customers have come to expect to solve their problems. In particular, our line of reactors, including trap reactors, line reactors, saturable reactors, current limiting reactors (CLR’s) are best of breed in the market place.

Engineering: Solid engineering design begins with the most advanced magnetics design software in the market, backed up with decades of design experience across a broad spectrum of products in transformers, reactors and inductors. Our engineering department has over 120+ years in custom magnetics design and fabrication of transformers, iron core reactors and air core reactors. We also take seriously our motto, “Built Like The Brooklyn Bridge”, applying what we term Brooklyn Bridge Engineering, B2E for short, as the inspiration for making the designs a work of art besides a masterpiece of engineering excellence!

Endurance: At the end of the day, the over-riding concern for our customers is reliability of their products in the field. Our conservative design, engineering and ISO certified manufacturing practices provide premium custom magnetics that our customers have come to count on for years of trouble free service in the most demanding applications. More than once we have heard from customers, “Practically indestructible,” when describing our products. Our customers in the oil & gas, transportation, automotive and electric vehicle, manufacturing, commercial facilities, communications, energy industries and renewable energy, know they can count on our drive isolation and neutral grounding transformers, load banks, trap reactors, line reactors, furnace transformers, plate transformers, and AC and DC inductors to provide literally decades of trouble free service, in the harshest of environments.

Our Story

The Power Magnetics Story

Carl T. Bannwart, the founder of Power Magnetics was a brilliant and charismatic individual who also had a strong, brilliantly creative streak — as many maverick trailblazers do. In 1968, Carl T., Don Kupper, his engineer, and George McCauley, his factory manager, founded Power Magnetics over drinks at his dining room table.

During that fall the company was incorporated and the factory was set up in rented space over on East State Street in part of the old Thropp Building. The first transformer was finished during Christmas break, and delivered to a New Jersey customer, CML Communications in North Jersey. Carl’s wife was the bookkeeper and generally helped out in the office.

In the summer of 1973, Carl’s son, Carl A. Bannwart started designing transformers and in December of 1973, graduated from Tufts University with a Bachelor’s Degree in Electrical Engineering, Magna Cum Laude.

During the next couple of years, life at Power Magnetics was very busy with the usual business challenges, complicated with Carl T.’s poor health. The chaos culminated in his death from a heart attack on May 15, 1975.

Carl A.’s brother Paul and he elected to buy the building in an economic development zone at Reservoir and Marion in 1983. Though the office in particular had been pretty thoroughly vandalized, they fixed the place up and moved in during the summer of 1984.

The next decade and a half, they started making CLR’s, current-limiting reactors, for the precipitator industry as well as load bank reactors and medium voltage trap reactors. The company also established supply contracts with several large American machine tool manufacturers.

In engineering, they started using Paul Goethe’s Optimized Program Services software and AutoCAD design. The development of furnace transformers for the American heat treating business added to the product lines. The phase changer business for commercial and industrial infrastructure for regional developers became a small business all its own.

Nonetheless, the basic question still remained unanswered: What major product line will take the company into the future? Carl knew that their best competitors had succeeded by finding a niche and thought by copying one of their “niches”, could find success; but this hadn’t worked. They had always been good at making reactors, but always felt that the construction was problematic and too labor intensive.

Then it came in a flash. Jack Agnew, in engineering, and Carl were discussing the merits of a particular manufacturing process. Jack commented on a methodology they both knew and Carl realized immediately that this was the way they needed to make reactors. It took a few years to get the process perfected because of capital required and time to put the pieces of the engineering puzzle together.

Understanding the power of the concept is related to the expression ‘there are very few bargains in life!’ How many of us have been wowed by a price, only to be disappointed later by quality or service? Similar rules apply in engineering; if you want more or better features: you generally have to pay for them. With the company’s new construction, its reactors run cooler, are quieter in operation, have a longer operating life AND are less costly to manufacture. In this case, Power Magnetics offers a true bargain and its reactors have become the industry standard.

Today it feels like the company is just getting warmed up. New business is being won from large, international customers based on the Innovation, Engineering and Endurance of the engineering that provides them unparalleled performance and reliability, and it seems there is more over the near horizon. The company has plans for a small addition to the building and plans to double its business capacity and employment in the next few years, and then with any luck double it again. The Trenton community and the company’s employees have been there for Power Magnetics through thick and thin, and it will be there for them. Its work is not done.

It may seem trite, but PMI enjoys an excellent reputation in the industry for Innovation, Engineering and Endurance that is widely recognized as being among the best of any manufacturer. The company continues to win business from customers who are increasingly unable to tolerate field failures from lesser products by other manufacturers. Truly, its products are “Built Like the Brooklyn Bridge” that exemplifies brilliant engineering and service durability far beyond what anyone ever expected.

As one VP of an aerospace firm told his Purchasing Manager recently, “Buy the reactors from Power Magnetics. Theirs are nearly impossible to destroy. They last forever!”

Carl T. Bannwart, the founder of Power Magnetics was a brilliant and charismatic individual who also had a strong, brilliantly creative streak — as many maverick trailblazers do. In 1968, Carl T., Don Kupper, his engineer, and George McCauley, his factory manager, founded Power Magnetics over drinks at his dining room table.

During that fall the company was incorporated and the factory was set up in rented space over on East State Street in part of the old Thropp Building. The first transformer was finished during Christmas break, and delivered to a New Jersey customer, CML Communications in North Jersey. Carl’s wife was the bookkeeper and generally helped out in the office.

In the summer of 1973, Carl’s son, Carl A. Bannwart started designing transformers and in December of 1973, graduated from Tufts University with a Bachelor’s Degree in Electrical Engineering, Magna Cum Laude.

During the next couple of years, life at Power Magnetics was very busy with the usual business challenges, complicated with Carl T.’s poor health. The chaos culminated in his death from a heart attack on May 15, 1975.

Carl A.’s brother Paul and he elected to buy the building in an economic development zone at Reservoir and Marion in 1983. Though the office in particular had been pretty thoroughly vandalized, they fixed the place up and moved in during the summer of 1984.

The next decade and a half, they started making CLR’s, current-limiting reactors, for the precipitator industry as well as load bank reactors and medium voltage trap reactors. The company also established supply contracts with several large American machine tool manufacturers.

In engineering, they started using Paul Goethe’s Optimized Program Services software and AutoCAD design. The development of furnace transformers for the American heat treating business added to the product lines. The phase changer business for commercial and industrial infrastructure for regional developers became a small business all its own.

Nonetheless, the basic question still remained unanswered: What major product line will take the company into the future? Carl knew that their best competitors had succeeded by finding a niche and thought by copying one of their “niches”, could find success; but this hadn’t worked. They had always been good at making reactors, but always felt that the construction was problematic and too labor intensive.

Then it came in a flash. Jack Agnew, in engineering, and Carl were discussing the merits of a particular manufacturing process. Jack commented on a methodology they both knew and Carl realized immediately that this was the way they needed to make reactors. It took a few years to get the process perfected because of capital required and time to put the pieces of the engineering puzzle together.

Understanding the power of the concept is related to the expression ‘there are very few bargains in life!’ How many of us have been wowed by a price, only to be disappointed later by quality or service? Similar rules apply in engineering; if you want more or better features: you generally have to pay for them. With the company’s new construction, its reactors run cooler, are quieter in operation, have a longer operating life AND are less costly to manufacture. In this case, Power Magnetics offers a true bargain and its reactors have become the industry standard.

Today it feels like the company is just getting warmed up. New business is being won from large, international customers based on the Innovation, Engineering and Endurance of the engineering that provides them unparalleled performance and reliability, and it seems there is more over the near horizon. The company has plans for a small addition to the building and plans to double its business capacity and employment in the next few years, and then with any luck double it again. The Trenton community and the company’s employees have been there for Power Magnetics through thick and thin, and it will be there for them. Its work is not done.

It may seem trite, but PMI enjoys an excellent reputation in the industry for Innovation, Engineering and Endurance that is widely recognized as being among the best of any manufacturer. The company continues to win business from customers who are increasingly unable to tolerate field failures from lesser products by other manufacturers. Truly, its products are “Built Like the Brooklyn Bridge” that exemplifies brilliant engineering and service durability far beyond what anyone ever expected.

As one VP of an aerospace firm told his Purchasing Manager recently, “Buy the reactors from Power Magnetics. Theirs are nearly impossible to destroy. They last forever!”

Engineering Philosophy

Power Magnetics, Inc. is the recognized leader in design and manufacturing of the industry’s highest performance and most reliable premium custom transformers, AC reactors and DC inductors. Since 1968, we have built custom magnetics for our global customers, some of the largest companies in the world, which exemplifies the three pillars of our philosophy: Innovation, Engineering and Endurance. You simply cannot buy a higher quality air cooled transformer or reactor. Period.

Innovation:

Our proprietary design methods assure our customers that our transformers, inductors and reactors are the highest performance magnetics for the given application. We go deeper than anyone, down to the physics of the devices to provide the innovation our customers have come to expect to solve their problems. In particular, our line of reactors, including trap reactors, line reactors, saturable reactors, current limiting reactors (CLR’s) are best of breed in the market place.

Engineering:

Solid engineering design begins with the most advanced magnetics design software in the market, backed up with decades of design experience across a broad spectrum of products in transformers, reactors and inductors. Our engineering department has over 120+ years in custom magnetics design and fabrication of transformers, iron core reactors and air core reactors. We also take seriously our motto, “Built Like The Brooklyn Bridge”, applying what we term Brooklyn Bridge Engineering, B2E for short, as the inspiration for making the designs a work of art besides a masterpiece of engineering excellence!

Endurance:

At the end of the day, the over-riding concern for our customers is reliability of their products in the field. Our conservative design, engineering and ISO certified manufacturing practices provide premium custom magnetics that our customers have come to count on for years of trouble free service in the most demanding applications. More than once we have heard from customers, “Practically indestructible,” when describing our products. Our customers in the oil & gas, transportation, automotive and electric vehicle, manufacturing, commercial facilities, communications and energy industries know they can count on our drive isolation and neutral grounding transformers, load banks, trap reactors, line reactors, furnace transformers, plate transformers, and AC and DC inductors to provide literally decades of trouble free service, in the harshest of environments.

Innovation:

Our proprietary design methods assure our customers that our transformers, inductors and reactors are the highest performance magnetics for the given application. We go deeper than anyone, down to the physics of the devices to provide the innovation our customers have come to expect to solve their problems. In particular, our line of reactors, including trap reactors, line reactors, saturable reactors, current limiting reactors (CLR’s) are best of breed in the market place.

Engineering:

Solid engineering design begins with the most advanced magnetics design software in the market, backed up with decades of design experience across a broad spectrum of products in transformers, reactors and inductors. Our engineering department has over 120+ years in custom magnetics design and fabrication of transformers, iron core reactors and air core reactors. We also take seriously our motto, “Built Like The Brooklyn Bridge”, applying what we term Brooklyn Bridge Engineering, B2E for short, as the inspiration for making the designs a work of art besides a masterpiece of engineering excellence!

Endurance:

At the end of the day, the over-riding concern for our customers is reliability of their products in the field. Our conservative design, engineering and ISO certified manufacturing practices provide premium custom magnetics that our customers have come to count on for years of trouble free service in the most demanding applications. More than once we have heard from customers, “Practically indestructible,” when describing our products. Our customers in the oil & gas, transportation, automotive and electric vehicle, manufacturing, commercial facilities, communications and energy industries know they can count on our drive isolation and neutral grounding transformers, load banks, trap reactors, line reactors, furnace transformers, plate transformers, and AC and DC inductors to provide literally decades of trouble free service, in the harshest of environments.